المنتجات الساخنة

Research Progress and Trends in Iron Metal Purification Processes

网页In this , we review latest research advances in high-purity iron purification methods and production processes and summarize the merits of each purification method.

Contact

Iron ore Wikipedia

网页Increasing iron ore demand, coupled with the depletion of high-grade hematite ores in the United States, led after World War II to the development of lower-grade iron ore sources, principally the utilization

Contact

Iron processing Ores, Surface Mining, Sintering, and

网页Ores Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed

Contact

Metallurgy Refining Britannica

网页The procedure is accomplished in three ways: refining by fire, by electrolytic, or by chemical methods. Iron, copper, and lead are fire-refined by selective oxidation. In this process, oxygen or air is added to the impure liquid

Contact

Iron Ore Processing an overview ScienceDirect Topics

网页Moreover, Bayan Obo was originally developed as an iron ore mine, and the rare earth concentrates produced were actually the tailings of the iron ore processing and did not

Contact

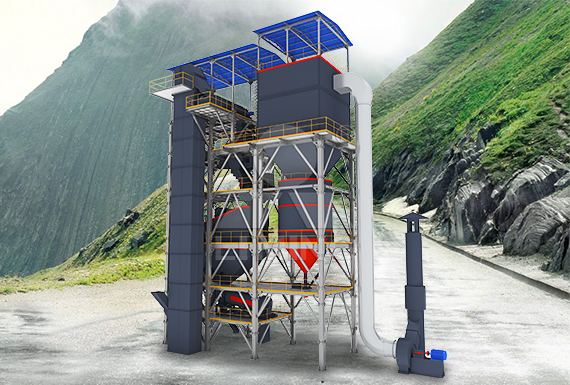

The six main steps of iron ore processing Multotec

网页Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Contact

Iron Ore Pelletization: Part I. Fundamentals TaylorFrancis

网页2021年3月15日A framework which describes how these binders interact not just with the pellet feed but also with each other is developed. This part describes the history, goals of

Contact

Mineral processing Metallurgy, Crushing

网页mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide

Contact

Metallurgy Refining Britannica

网页Refining is the final procedure for removing (and often recovering as by-products) the last small amounts of impurities left after the major extraction steps have been completed. It leaves the major metallic element in a

Contact

Beneficiation Strategies for Removal of Silica and Alumina

网页2021年11月24日The processes selected to reduce impurity levels of these lower-grade iron ores will depend on the ore mineralogy and a thorough understanding of the separation process dynamics. The major concentration methods that may be applied to upgrade lower-grade lump iron ores include magnetic separation, wet and dry heavy media separation,

Contact

The Preparation of High-Purity Iron (99.987%) Employing a

网页2020年4月14日In this study, high-purity iron with purity of 99.987 wt.% was prepared employing a process of direct reduction-melting separation-slag refining. The iron ore after pelletizing and roasting was reduced by hydrogen to obtain direct reduced iron (DRI). Carbon and sulfur were removed in this step and o

Contact

Iron Ore Pelletization: Part I. Fundamentals TaylorFrancis

网页2021年3月15日The behavior of iron ore pellet binders is complex. Any pellet binder is subject to a handful of practical requirements: that it be readily dispersed through a pellet, that it effectively controls the movement of water within the pellet, and that it contributes to the inter-particle bonding within the pellet.

Contact

The six main steps of iron ore processing Multotec

网页Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Contact

US5312602A Method for purifying iron oxide Google Patents

网页Inventor Karl J. V. Svensson Bo H. Zander Current Assignee Report of Investigation no. 7812) that the SiO 2 content in iron ore concentrate can be reduced to a significant degree by leaching in lye IRON OXIDE PURIFICATION PROCESS US07/941,407 US5312602A (en) 1990-11-22: 1992-09-08: Method for

Contact

(PDF) Hydrogen Plasma Processing of Iron Ore

网页2017年6月21日Iron is currently produced by carbothermic reduction of oxide ores. This is a multiple-stage process that requires large-scale equipment and high capital investment, and produces large amounts of

Contact

A kind of iron powder method of purification Google Patents

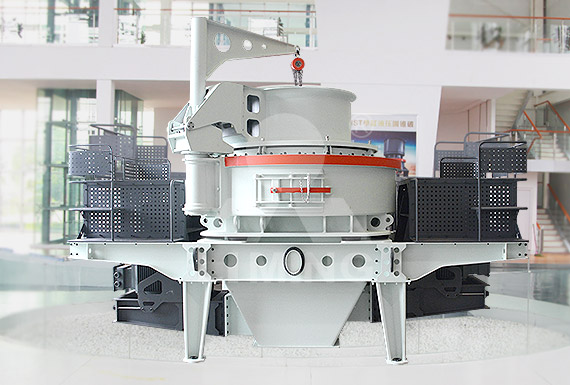

网页The present invention relates to a kind of iron powder method of purification, include the following steps that big grain size is broken:Iron ore is placed in the first crusher and is...

Contact

Process of removing iron impurities from ores Google Patents

网页A process of removing iron impurities from ores, particularly useful for removing stains of iron impurities adhered to silica sand particles, comprises grinding the ore, washing and...

Contact

Mineral processing Metallurgy, Crushing

网页mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide

Contact

Iron Production Chemistry LibreTexts

网页The production of iron from its ore involves an oxidation-reduction reaction carried out in a blast furnace. Iron ore is usually a mixture of iron and vast quantities of impurities such as sand and clay referred to as gangue. The iron found

Contact

Metallurgy Refining Britannica

网页Refining is the final procedure for removing (and often recovering as by-products) the last small amounts of impurities left after the major extraction steps have been completed. It leaves the major metallic element in a

Contact

Beneficiation Strategies for Removal of Silica and Alumina

网页2021年11月24日The processes selected to reduce impurity levels of these lower-grade iron ores will depend on the ore mineralogy and a thorough understanding of the separation process dynamics. The major concentration methods that may be applied to upgrade lower-grade lump iron ores include magnetic separation, wet and dry heavy media separation,

Contact

Extracting iron Redox, extraction of iron and transition

网页Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as haematite contain iron (III) oxide, Fe2O3. The oxygen must be removed from the iron (III)...

Contact

The Preparation of High-Purity Iron (99.987%) Employing a

网页2020年4月14日In this study, high-purity iron with purity of 99.987 wt.% was prepared employing a process of direct reduction-melting separation-slag refining. The iron ore after pelletizing and roasting was reduced by hydrogen to obtain direct reduced iron (DRI). Carbon and sulfur were removed in this step and o

Contact

Iron Ore Pelletization: Part I. Fundamentals TaylorFrancis

网页2021年3月15日The behavior of iron ore pellet binders is complex. Any pellet binder is subject to a handful of practical requirements: that it be readily dispersed through a pellet, that it effectively controls the movement of water within the pellet, and that it contributes to the inter-particle bonding within the pellet.

Contact

US5312602A Method for purifying iron oxide Google Patents

网页Inventor Karl J. V. Svensson Bo H. Zander Current Assignee Report of Investigation no. 7812) that the SiO 2 content in iron ore concentrate can be reduced to a significant degree by leaching in lye IRON OXIDE PURIFICATION PROCESS US07/941,407 US5312602A (en) 1990-11-22: 1992-09-08: Method for

Contact

A kind of iron powder method of purification Google Patents

网页The present invention relates to a kind of iron powder method of purification, include the following steps that big grain size is broken:Iron ore is placed in the first crusher and is...

Contact

Silver processing Refining, MiningUses Britannica

网页The lustre of the pure metal is due to its electron configuration, which results in its reflecting all electromagnetic radiation of wavelengths longer than 3000 angstroms (3000 angstroms is in the ultraviolet range).

Contact