المنتجات الساخنة

Comminution and classification technologies of iron ore

网页2022年1月1日Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

Contact

The six main steps of iron ore processing Multotec

网页1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to

Contact

Iron Ore production in the Pilbara

网页Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products.

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日The process "Comminution" involves size reduction and size-wise classification called as screening or separation. The objective

Contact

CN210585299U Iron ore crushing screening dry separation

网页The utility model discloses an iron ore crushing and screening dry separation system, which belongs to the technical field of iron ore dressing and comprises a first-stage

Contact

Life cycle assessment of iron ore mining and processing

网页2015年12月31日DOI: 10.1016/B978-1-78242-156-6.00020-4 Authors: Nawshad Haque The Commonwealth Scientific and Industrial Research Organisation Terry Norgate Abstract and Figures Mining of iron ore is a

Contact

Beneficiation of Iron Ores IspatGuru

网页2014年4月3日satyendra April 3, 2014 2 Comments DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation Beneficiation of Iron Ores Iron ore is a mineral which is used after

Contact

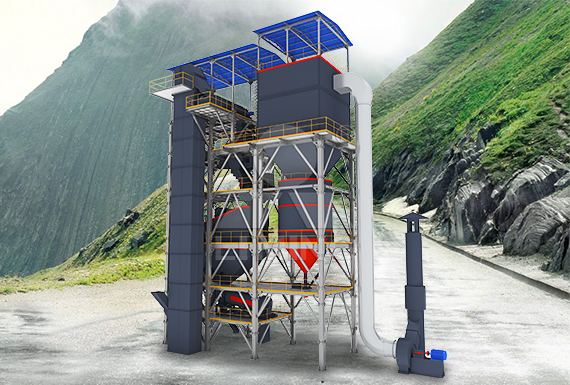

Iron Ore Processing,Crushing,Grinding Plant Machine

网页Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

Contact

Beneficiation of Iron Ores PHDessay

网页2018年3月27日For benefaction of a particular iron ore the emphasis is usually to develop a cost effective flow she et incorporating necessary crushing, grinding, screening and

Contact

Challenges and opportunities in the iron ore crusher

网页2019年8月8日The description of iron ore crushing process. In the crushing process of lean iron ore, in order to obtain the best process configuration and the lowest crushing cost, it is necessary to master the

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore by

网页The dephosphorization treatment of the pre-reduced iron ore by me-chanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the mechanical property of the reduced iron ore phase. KEY WORDS: high phosphorus iron ore; dephosphorization treatment; solid state reduction; mechanical

Contact

Iron Ore production in the Pilbara

网页Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation. Processing may be wet or dry.

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Contact

Iron Ore 2nd Edition Elsevier

网页2021年12月2日8.2 Iron ore crushing and screening. 8.3 Iron ore grinding and classification. 8.4 Future trends in iron ore comminution and classification. 9.5 Challenges and recent advances in upgrading low-grade iron ores using magnetic separation. 9.6 Summary. References. Chapter 10 Non-magnetic physical separation

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore

网页2011年2月17日The dephosphorization treatment of the pre-reduced iron ore by mechanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the mechanical property

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore by

网页Mechanical crushing of the reduced iron ore result- ed in the elongation of the ductile reduced iron particles and the entrapment of the gangue within the elongated reduced iron particles, thereby hindering effective separation by screening methods.1,2)Therefore, the application of uni-axial direct mechanical pressure was avoided in the present

Contact

11.24 Metallic Minerals Processing US EPA

网页The number of crushing steps necessary to reduce ore to the proper size vary with the type of ore. Hard ores, including some copper, gold, iron, and molybdenum ores, may require as much as a tertiary crushing. Softer ores, such as some uranium, bauxite, and titanium/zirconium ores, require little or no crushing.

Contact

Understanding Iron Ores and Mining of Iron Ore

网页2015年4月3日High grade iron ores (iron content greater than 62 %) are simply crushed, screened and shipped directly to the iron making unit (e.g. blast furnace). Low grade iron ores containing lower iron content need

Contact

Iron ore washing process and equipment LZZG

网页April.14,2021 Common iron ore washing process The commonly used method of ore dressing in iron ore washing plants is gravity separation. The gravity separation method does not pollute the environment and has high ore dressing efficiency.

Contact

Processes for Beneficiation of Iron Ores IspatGuru

网页2015年3月28日Crushing and screening are an integral part of ore producing facilities. Crushing usually involves a primary crusher and secondary crushers operating in closed circuit with vibrating screens.

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore by

网页The dephosphorization treatment of the pre-reduced iron ore by me-chanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the mechanical property of the reduced iron ore phase. KEY WORDS: high phosphorus iron ore; dephosphorization treatment; solid state reduction; mechanical

Contact

Iron Ore 2nd Edition Elsevier

网页2021年12月2日8.2 Iron ore crushing and screening. 8.3 Iron ore grinding and classification. 8.4 Future trends in iron ore comminution and classification. 9.5 Challenges and recent advances in upgrading low-grade iron ores using magnetic separation. 9.6 Summary. References. Chapter 10 Non-magnetic physical separation

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore

网页2011年2月17日The dephosphorization treatment of the pre-reduced iron ore by mechanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the mechanical property

Contact

Dephosphorization Treatment of High Phosphorus Iron Ore by

网页Mechanical crushing of the reduced iron ore result- ed in the elongation of the ductile reduced iron particles and the entrapment of the gangue within the elongated reduced iron particles, thereby hindering effective separation by screening methods.1,2)Therefore, the application of uni-axial direct mechanical pressure was avoided in the present

Contact

(PDF) Overview of Mineral Processing Methods

网页2015年8月3日Abstract and Figures. The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation

Contact

11.24 Metallic Minerals Processing US EPA

网页The number of crushing steps necessary to reduce ore to the proper size vary with the type of ore. Hard ores, including some copper, gold, iron, and molybdenum ores, may require as much as a tertiary crushing. Softer ores, such as some uranium, bauxite, and titanium/zirconium ores, require little or no crushing.

Contact

Iron ore washing process and equipment LZZG

网页April.14,2021 Common iron ore washing process The commonly used method of ore dressing in iron ore washing plants is gravity separation. The gravity separation method does not pollute the environment and has high ore dressing efficiency.

Contact

Iron Ore Processing Solution Eastman Rock Crusher

网页The processing of iron ore mainly goes through the processes of crushing, grinding, beneficiation, and drying, among which the crushing process is the primary and important link in iron ore processing. Iron ore

Contact

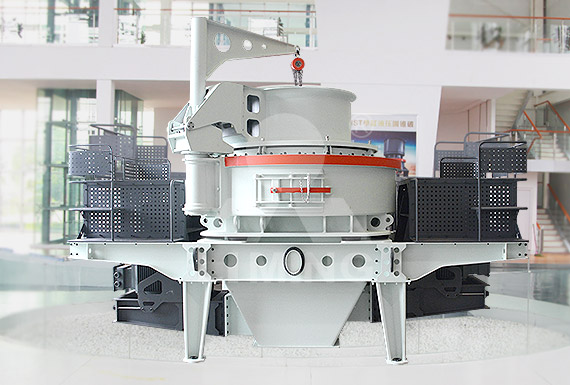

Iron Ore Crusher/ Iron Ore Processing Plant/ Iron

网页Iron ore crusher consists of coarse crushing, medium crushing and fine crushing. Among the iron ore crushing flow, the vibrator feeder, coarse crushing machine, medium crushing machine, screening machine,

Contact