المنتجات الساخنة

Operational parameters affecting the vertical roller mill

网页2017年4月1日The model consists of grinding and separation sections. For the modelling of the grinding operation, breakage rates of the particles are correlated with design

Contact

Grinding process optimization IEEE Xplore

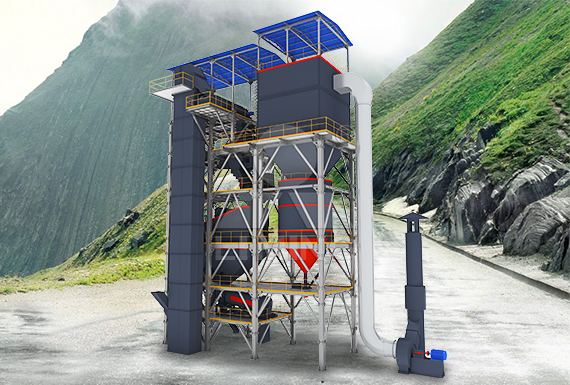

网页2017年6月19日The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically

Contact

Analysis and Optimization of Grinding Performance

网页2022年1月23日This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the

Contact

Vertical roller mill for raw Application p rocess materials

网页In the cement grinding process, the vertical roller mill having high grinding performance is applied especially cement grinding instead of the conventional tube mill. For further

Contact

(PDF) Design and Realization Of Roller Mill Control

网页2012年12月31日Design and Realization Of Roller Mill Control System Authors: QianHong Wang Qiang Zhang XiaoLi Bai HongLiang Yu Abstract and Figures a Distributed Control System (DCS) of cement raw materials

Contact

Vibration Analysis of a Vertical Roller Mill: Modeling

网页2014年7月25日In this , vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM. The mathematical model is

Contact

(PDF) Matrix Model Simulation of a Vertical Roller Mill

网页2014年5月1日The purpose of this study is to reveal the mechanism of unstable vibration occurring in the grinding operation of roller mills and to show the design guidelines for reducing the vibration.

Contact

quadropol® vertical roller mill thyssenkrupp

网页quadropol® vertical roller mill thyssenkrupp is one of the few full-range suppliers for the cement industry from individual machines, all the way up to complete cement plants, and this since decades. The market

Contact

Grinding process optimization IEEE Xplore

网页2017年6月19日The modular design of the vertical roller mill comprising 4 to 6 grinding rollers allows the continuation of mill operation even if one roller module is not available. The same applies to the innovative multi drive design of the mill drive consisting of up to 6 identical drive units in the range of 2,000 kW each.

Contact

Grinding Process Optimization Featuring Case Studies

网页The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the demand for...

Contact

Vertical roller mill for raw Application p rocess materials

网页The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely adopted. A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table.

Contact

Selected Aspects of Modelling and Design Calculations of

网页2021年3月1日An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agri-, chemical, power and construction industries were presented. Quick designing of the machines required existence of adequate mathematical models. Within the framework of the study’s realization, a mathematical

Contact

Vibration Analysis of a Vertical Roller Mill: Modeling and

网页2014年7月25日In this , vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM. The mathematical model is derived and simulated for a set of

Contact

(PDF) Matrix Model Simulation of a Vertical Roller

网页2014年5月1日Matrix Model Simulation of a Vertical Roller Mill with High-Efficiency Slat Classifier Authors: Jozsef Faitli University of Miskolc Peter Czel Abstract and Figures On-site operational tests...

Contact

On the Optimization Procedure of Rolling Mill

网页2012年9月27日Eight optimization steps pass schedule generation, work roll determination, backup roll diameter, mill type selection, mill window layout, mill housing dimension, roll profile calculation,...

Contact

Application of Design Failure Modes and Effect Analysis

网页Vertical roller mills (VRM) are well accepted as most effectual means for grinding raw material in cement and power generation industry. These mills are driven by heavy duty gearboxes with...

Contact

Optimal Design and Force Analysis for Key Components of

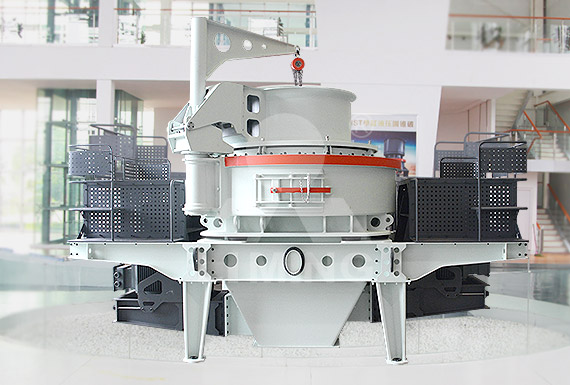

网页Abstract. Abstract: As an efficient large-scale grinding and drying equipment, the vertical roller mill is widely used in many fields, especially in the fields of grinding cement raw meal, clinker, and blast furnace slag. In this thesis, the key components of the vertical roller mill are preferred according to the design requirements, including

Contact

Grinding process optimization IEEE Xplore

网页2017年6月19日The modular design of the vertical roller mill comprising 4 to 6 grinding rollers allows the continuation of mill operation even if one roller module is not available. The same applies to the innovative multi drive design of the mill drive consisting of up to 6 identical drive units in the range of 2,000 kW each.

Contact

Grinding Process Optimization Featuring Case Studies

网页The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the demand for...

Contact

A study of operating parameters of a roller mill with a new

网页2019年2月21日The influence of modifying the working unit by inserting a vertical plate between cooperating rollers on performance indicators fineness, energy among other things, on friction conditions, collision, cutting, new mill design features. The new design of roller mill assembly consists of two rotating rollers with

Contact

Selected Aspects of Modelling and Design Calculations of

网页2021年3月1日An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agri-, chemical, power and construction industries were presented. Quick designing of the machines required existence of adequate mathematical models. Within the framework of the study’s realization, a mathematical

Contact

Holderbank Cement engineering book Archive

网页This stone deals in first place with roller mills for raw material processing. For grinding coal, slag, cement, etc., adaptations to mills and systems have to be made. 2. FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in one compact piece of equipment: ¢ Grinding ? Drying ¢ Separation ¢ Transport

Contact

Vibration Analysis of a Vertical Roller Mill: Modeling and

网页2014年7月25日In this , vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM. The mathematical model is derived and simulated for a...

Contact

(PDF) Matrix Model Simulation of a Vertical Roller

网页2014年5月1日Matrix Model Simulation of a Vertical Roller Mill with High-Efficiency Slat Classifier Authors: Jozsef Faitli University of Miskolc Peter Czel Abstract and Figures On-site operational tests...

Contact

Operational Experience from the United States' First Vertical

网页to ball mills. The simple and compact vertical mill layout is cost competitive to build and offers many options for layout, even in existing plants. Today significant operating experience has been accumulated with vertical mills ranging from plant design and layout to operation with multiple types of product. One of the main focus

Contact

Performance Evaluation of Vertical Roller Mill in Cement

网页FIGURE 1. Schematic view of vertical roller mill and streams TABLE 1. Name of the streams Prior to performing sampling campaign, operating conditions should be followed from the control...

Contact

Optimal Design and Force Analysis for Key Components of

网页Abstract. Abstract: As an efficient large-scale grinding and drying equipment, the vertical roller mill is widely used in many fields, especially in the fields of grinding cement raw meal, clinker, and blast furnace slag. In this thesis, the key components of the vertical roller mill are preferred according to the design requirements, including

Contact