المنتجات الساخنة

Operational parameters affecting the vertical roller mill

网页2017年4月1日 The model consists of grinding and separation sections. For the modelling of the grinding operation, breakage rates of the particles are correlated with design

Contact

HLM Vertical Roller Mill hcmilling

网页Guilin Hongcheng’s HLM vertical roller mill has the advantages of high grinding efficiency, low power consumption, large feeding particle size, easy adjustment of product fineness,

Contact

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

网页2019年9月12日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid:́ Increased production rate,

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have

Contact

Best HLM Vertical Roller Mill Manufacturer and Factory

网页Vertical grinding mill is a specialized milling equipment integrates grinding, drying and classifying, and conveying in one unit. HLM series vertical roller mill machine has the

Contact

Vertical roller grinding mill LM series Henan LIMING

网页Find out all of the information about the Henan LIMING Heavy Industry Science and Technology product: vertical roller grinding mill LM series . Contact a supplier or the

Contact

Copper ore grinding in a mobile vertical roller mill pilot plant

网页2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers. It has been used mainly for

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN

网页2017年10月27日 The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process

Contact

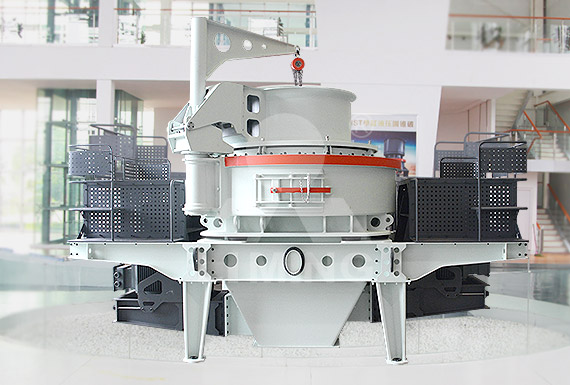

Vertical roller mill Hengtu Machinery

网页The working principle of vertical roller mill: The main motor of the vertical roller mill drives the grinding plate in the grinding machine through the transmission of the reducer. The

Contact

Vertical Roller Mills Ammermann Pty Ltd

网页The roller grinding mill technology, patented in 1928 and continuously developed since then has become synonymous with Loesche’s pioneering engineering and know-how. The

Contact

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

网页2019年9月12日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid:́ Increased production rate, energy savinǵ Higher fineness, faster strength development́ Reduced vibration, less weaŕ Reduced water injection, less pre-hydratioń Improved particle size distribution, better concrete

Contact

HLM Vertical Roller Mill new.hcmilling

网页HLM vertical mill has become the mainstream equipment in the pulverizing industry with the following advantages: efficient grinding, lower power consumption, larger feeding size, adjustable fineness, simple process flow, space-saving, lower noise, smaller air pollution, easy maintenance, lower operation cost, longer working life of wearing parts...

Contact

Vertical roller grinding mill LUM1125X Henan LIMING

网页Specifications Technical Data Production Capacity: 5-14Tons / Hour Granularity of the feeding material D90 (mm): < 10 Max. 15mm Fineness (mm): Generally in 0.045-0.02, the finest can reach 0.01 Moisture of the feeding material: < 3% Advantages of LUM1125X Vertical Roller Mill 1. High grinding efficiency, little pollution to the final products.

Contact

Analysis and Optimization of Grinding Performance of

网页2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 The hot gases from the pre heater enter the mill and are used for drying material in the mills. The ball mill and VRM are explained in further sections of this thesis. The vertical roller mill can grind the material of particle size of 5% of the grinding roller diameter. The feed size is generally 40 to 100 mm and can reach 120 mm in case

Contact

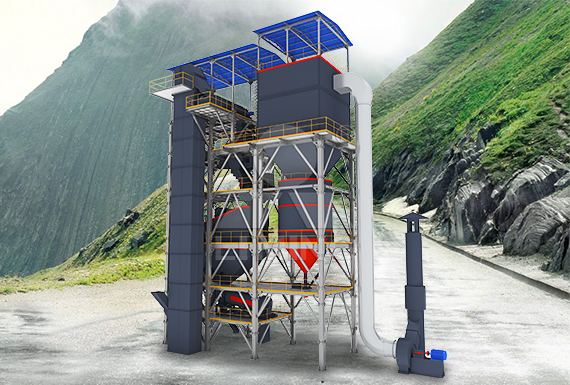

Vertical roller grinding mill LM series Henan LIMING

网页LM Vertical Mill High drying efficiency, Low running cost, Good environmental effect LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing non-metallic minerals, pulverized coal and slag. Its coverage area is reduced by 5...

Contact

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

网页The fundamental difference between the ATLAS and other table-roller mills is the bearing arrangement for the grinding table which is incorporated into the base of the mill. This enables an operation with a standard design gearbox instead of the typical gearboxes with integrated bearing section with long delivery times.

Contact

Petroleum Coke HLM Vertical Roller Mill hcmilling

网页Petroleum Coke HLM Vertical Roller Mill Top equipment of Petroleum Coke large-scale processing. High Capacity, Advanced Technology, High Efficiency Max feeding size:50mm Capacity:5-200t/h Fineness:200-325 mesh (75-44μm)

Contact

VRPM AMCL Machinery Limited

网页The Vertical Roller Pre-grinding Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co. Ltd. Japan. These machines are used for substantial power saving and capacity

Contact

Finish grinding with vertical roller mills-operating data

网页2002年5月9日 Finish grinding with vertical roller mills-operating data Abstract: Vertical roller mills offer significant potential for savings when used for finish grinding. Two installations in Peru and the Dominican Republic are being examined with specific data on cement production, product fineness, specific power consumption and concrete strength.

Contact

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

网页2019年9月12日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid:́ Increased production rate, energy savinǵ Higher fineness, faster strength development́ Reduced vibration, less weaŕ Reduced water injection, less pre-hydratioń Improved particle size distribution, better concrete

Contact

Analysis and Optimization of Grinding Performance of

网页2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 The hot gases from the pre heater enter the mill and are used for drying material in the mills. The ball mill and VRM are explained in further sections of this thesis. The vertical roller mill can grind the material of particle size of 5% of the grinding roller diameter. The feed size is generally 40 to 100 mm and can reach 120 mm in case

Contact

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

网页The fundamental difference between the ATLAS and other table-roller mills is the bearing arrangement for the grinding table which is incorporated into the base of the mill. This enables an operation with a standard design gearbox instead of the typical gearboxes with integrated bearing section with long delivery times.

Contact

Vertical roller grinding mill LM series Henan LIMING

网页LM Vertical Mill High drying efficiency, Low running cost, Good environmental effect LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing non-metallic minerals, pulverized coal and slag. Its coverage area is reduced by 5...

Contact

An energy based comparison of vertical roller mills and

网页2015年3月10日 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests.The mill provides the technical options to vary process parameters like air-flow, mass flow, grinding force and

Contact

Vertical roller mill, Vertical roller grinding mill All

网页Final grain size: 170 µm Output: 10 t/h 320 t/h Motor power: 250, 220, 280, 185 kW. LM Vertical Mill High drying efficiency, Low running cost, Good environmental effect LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying

Contact

Finish grinding with vertical roller mills-operating data

网页2002年5月9日 Finish grinding with vertical roller mills-operating data Abstract: Vertical roller mills offer significant potential for savings when used for finish grinding. Two installations in Peru and the Dominican Republic are being examined with specific data on cement production, product fineness, specific power consumption and concrete strength.

Contact

Vertical Pre-Grinding Mill PENGFEI Group

网页2021年10月12日 High productivity but low energy consumption. The vertical pre-grinding mill makes use of pressing force and shearing force for material grinding. It offers better grinding results than roller mills. When used for cement raw material and cement clinker pre-grinding, the pre-grinding machine can increase production capacity by 100% and 50%

Contact

VRPM AMCL Machinery Limited

网页The Vertical Roller Pre-grinding Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co. Ltd. Japan. These machines are used for substantial power saving and capacity

Contact