المنتجات الساخنة

Comparative studies of two cationic collectors in the

网页2017年10月10日 The flotation experiments carried out on the single minerals indicate that the maximum flotation recovery of pyrolusite in the presence of DDA and DTAC are 89% and 73%, respectively. These recoveries are achieved at a pH of 7–8 when the dosage

Contact

Microwave-enhanced reduction of manganese from a low

网页2022年4月4日 Therefore, techniques related to the recovery of manganese from pyrolusite (MnO 2), one of the low-grade manganese oxide ore, become more and more critical.

Contact

Beneficiation of Manganese Ore Using Froth Flotation

网页2019年1月1日 Manganese ores of major commercial importance are pyrolusite (MnO 2, Mn about 63.2%)psilomelane. From this study the recovery of MnO 2 by using froth

Contact

(PDF) Evaluation of pyrolusite flotation behavior using a

网页2015年9月1日 Most of these studies revealed that manganese flotation using sodium silicate, sodium hydroxide, and oleic acid was found to be effective for the removal of

Contact

Evaluation of pyrolusite flotation behavior using a cationic

网页2015年4月15日 Abstract. Floatability of pyrolusite from an Iranian low grade manganese ore (13.6% MnO) containing calcite as the main gangue mineral was investigated with

Contact

The flotation of low-grade manganese ore using a novel

网页2015年2月5日 In this , a novel hydroxamic acid had been synthesized for the flotation separation of rhodochrosite from manganese ore, and the flotation performance by the

Contact

Effect of biological pretreatment on flotation recovery of

网页2014年5月1日 Pyrolusite ore flotation practice is well described in the technical literature and typically involves flotation of manganese dioxide using octyl hydroxamate as

Contact

Separation of pyrolusite from calcite by anionic flotation

网页2013年1月1日 In this research the flotation behavior of pyrolusite and calcite and their separation from each other using oleic acid as an anionic collector were investigated.

Contact

Agglomeration Flotation of Manganese Ore 911

网页2020年11月5日 The manganese minerals have been identified as psilomelane, hollandite, coronadite, and, pyrolusite with minor amounts of rhodonite and rhodochrosite. The

Contact

Flotation Manganese Ore Froth Flotation (Sulphide

网页2023年5月12日 7 years ago Like Mineralogy would be a good start I presume that we are dealing with pyrolusite and what types of carbonates: limestone, dolomite, Also grain

Contact

Collector1 Springer

网页2017年8月28日 Keywords: Pyrolusite, manganese ore, flotation, cationic collector, depressant. DOI: 10.1134/S1062739114050184 and high-intensity magnetic separation are usually used to upgrade manganese ores. Flotation is one of the developed processes for the beneficiation of lower grade and more refractory resources especially in fine size

Contact

Oxidative Leaching of Low-Grade Pyrolusite in Alkaline

网页2022年12月3日 When the oxygen partial pressure was 0.3 MPa, the conversion of the manganese in pyrolusite sample JM-1 reached the maximum (99.05%); and when the oxygen partial pressure was 0.5 MPa, the conversion of the manganese in pyrolusite sample JM-2 reached the maximum (95.08%). Teng Q (2014) Effect of biological pretreatment

Contact

Microwave-enhanced reduction of manganese from a low

网页2022年4月4日 Manganese is mainly obtained from pyrolusite and magnesite (Deng et al. 2019 ). With the increase of manganese consumption, the resource reserves of high-grade manganese ore are gradually exhausted (Xie et al. 2014; Biswal et al. 2015 ), thus manganese is expected to be in short supply in the next decade.

Contact

Effect of biological pretreatment on flotation recovery of

网页2014年5月1日 R NATARAJAN et al. Adsorption and flotation behavior of manganese dioxide in the presence of octyl hydroxamate [J] International Journal of Mineral Processing (1983) DW FUERSTENAU et al. On using electrokinetics to interpret the flotation and interfacial behavior of manganese dioxide [J] International Journal of Mineral Processing

Contact

Effect of biological pretreatment on flotation recovery of

网页2014年5月1日 Pyrolusite ore flotation practice is well described in the technical literature and typically involves flotation of manganese dioxide using octyl hydroxamate as collector [1]. Hydroxamate forms strong chelate bonds with manganese ions and consequently strongly chemisorbs on manganese-containing minerals.

Contact

(PDF) The Role of Interaction between Paenibacillus

网页2017年4月10日 The review of flotation studies reveals that flotation of manganese oxide minerals can enhance the manganese grade by removal of clay or other gangue minerals but removal of iron is...

Contact

O-Isobutyl-N-hydroxyethyl Thionocarbamate: Molecular

网页2023年6月25日 Herein, a chelating collector, O-isobutyl-N-hydroxyethyl thionocarbamate (IBHETC), was synthesized by using a safe ethanolamine instead of volatile gas ethylamine, and its molecular behavior and flotation performance for chalcopyrite were carefully investigated.Nuclear magnetic resonance (NMR) (1D and 2D), molecular dynamics (MD)

Contact

Beneficiation of manganese ores with particular

网页2022年2月19日 complex reagents, magnetic concentration following a reducing roast is the only possible method of treatment. Gravity concentration (heavy medium, tabling, and jigging), froth flota tion, agglomeration tabling or table flotation, and magnetic concentration are beneficiation processes used in the treatment of manganese ores. Careful

Contact

Agglomeration Flotation of Manganese Ore 911

网页2020年11月5日 The manganese minerals have been identified as psilomelane, hollandite, coronadite, and, pyrolusite with minor amounts of rhodonite and rhodochrosite. The principal gangue minerals are quartz, opal, kaolinite montmorillonite, calcite,

Contact

Flotation Manganese Ore Froth Flotation (Sulphide

网页2023年5月12日 7 years ago Like Mineralogy would be a good start I presume that we are dealing with pyrolusite and what types of carbonates: limestone, dolomite, Also grain sizes and associations. Why have you gone for flotation? With the SG differences, gravity is an obvious choice, at least for pre-concentration.

Contact

Collector1 Springer

网页2017年8月28日 Keywords: Pyrolusite, manganese ore, flotation, cationic collector, depressant. DOI: 10.1134/S1062739114050184 and high-intensity magnetic separation are usually used to upgrade manganese ores. Flotation is one of the developed processes for the beneficiation of lower grade and more refractory resources especially in fine size

Contact

Oxidative Leaching of Low-Grade Pyrolusite in Alkaline

网页2022年12月3日 When the oxygen partial pressure was 0.3 MPa, the conversion of the manganese in pyrolusite sample JM-1 reached the maximum (99.05%); and when the oxygen partial pressure was 0.5 MPa, the conversion of the manganese in pyrolusite sample JM-2 reached the maximum (95.08%). Teng Q (2014) Effect of biological pretreatment

Contact

Microwave-enhanced reduction of manganese from a low

网页2022年4月4日 Manganese is mainly obtained from pyrolusite and magnesite (Deng et al. 2019 ). With the increase of manganese consumption, the resource reserves of high-grade manganese ore are gradually exhausted (Xie et al. 2014; Biswal et al. 2015 ), thus manganese is expected to be in short supply in the next decade.

Contact

(PDF) The Role of Interaction between Paenibacillus

网页2017年4月10日 The review of flotation studies reveals that flotation of manganese oxide minerals can enhance the manganese grade by removal of clay or other gangue minerals but removal of iron is...

Contact

Chapter 8 Flotation of Non-Sulphide Minerals Hacettepe

网页2015年10月19日 When pyrolusite (MnO 2) is floated with oleate as collector two maxima are seen in the flotation response. The pzc for this mineral is 7.4. Flotation of pyrolusite (MnO 2) with 1x10-4M acetate The strong flotation response at pH 8.5 when the surface is negatively charged cannot be explained by physical adsorption of an anionic collector.

Contact

Manganese SpringerLink

网页2017年11月25日 The pyrolusite (MnO 2) is the most important ore. The main impurities are alumina, silica and iron oxide. The ores of manganese can be divided into four categories determined by grade and quality, as follows: (1) Exceptionally high grade ore characterized by a high content of manganese dioxide.

Contact

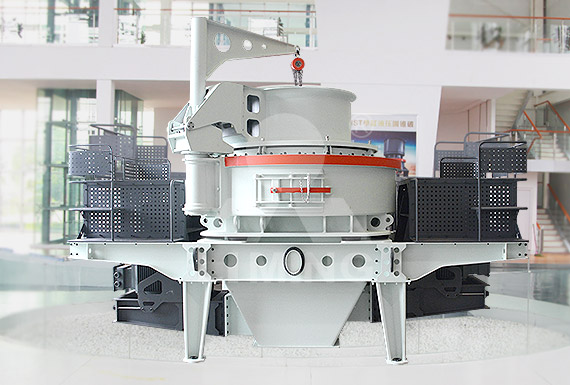

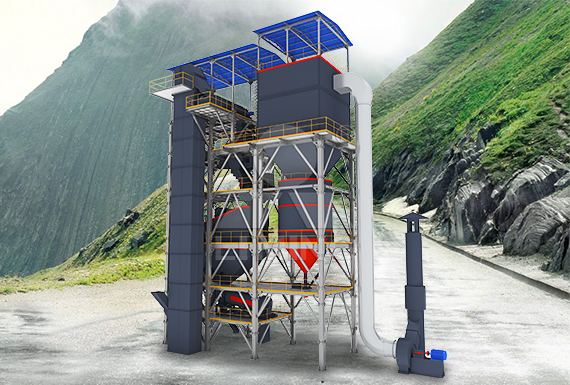

5 Commonly Used Manganese Processing Methods

网页2021年6月29日 There are 5 commonly used manganese ore beneficiation methods include ore washing, gravity separation, magnetic separation, flotation roasting. Ore Washing Washing is a method of separating the ore and mud from the raw ore under the action of hydraulic, mechanical and self-friction, thereby improving the grade of the ore.

Contact

Differences and Applications of Magnetic Separation and

网页2023年2月15日 Magnetic separation and froth flotation are common beneficiation equipment in the ore dressing process, mainly used to beneficiate the required ore. The manganese oxide ore process concludes ore washing-jigging-strong magnetic separation process. After crushing to less than 70 mm, the ore need to be washed, sieved and

Contact

Magnetic flotation Justia Patents Search

网页The concentrated mineral particles may be detached from the magnetic particles by any suitable method. For example, the flotation reagent may be destroyed with oxidising reagents such as hypochlorite, hydrogen peroxide or air, or by pyrolitic degradation. Alternatively, the flotation reagent may be displaced by ions such as cyanide or hydroxide.

Contact

Flotation Manganese Ore Froth Flotation (Sulphide

网页2023年5月12日 7 years ago Like Mineralogy would be a good start I presume that we are dealing with pyrolusite and what types of carbonates: limestone, dolomite, Also grain sizes and associations. Why have you gone for flotation? With the SG differences, gravity is an obvious choice, at least for pre-concentration.

Contact